Getting your classification right

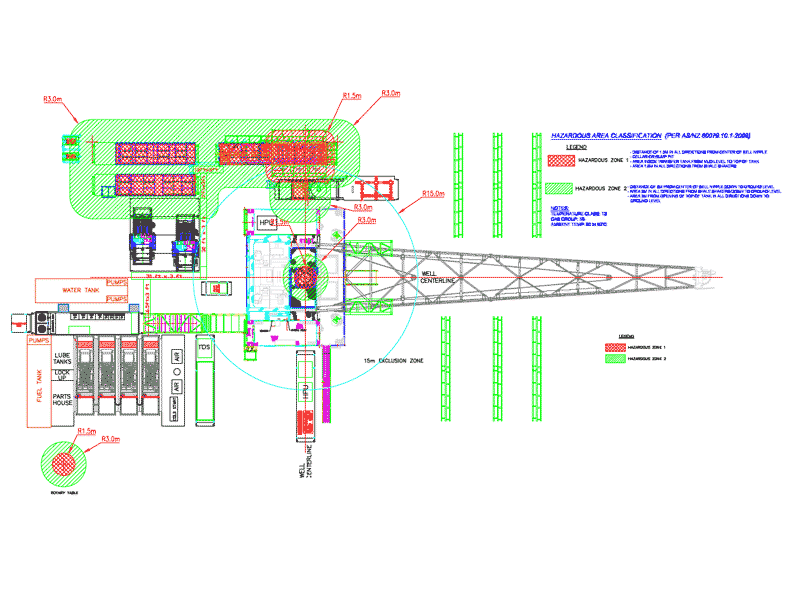

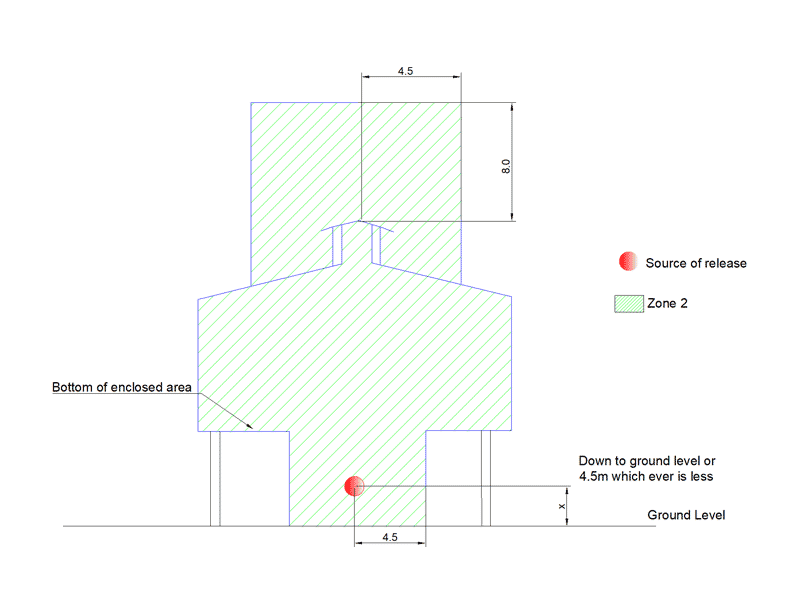

Your hazardous area classification study should be conducted in the early stages of

plant design, and be adapted and updated as the plant is being constructed, to reflect the “as built” plant. But your compliance

requirements shouldn’t end there: if the plant has been established for some time, then reviewing the classification is just as important to

ensure the details are still correct.

Area classification is mandatory as noted in the wiring rules (AS/NZS 3000) under section 7.7, which refers to two main classification

standards used in Australia.

Explosive atmospheres

Part 10:1 Classification of areas

Explosive gas atmospheres

(IEC 60079-10-1, Ed.1.0(2008) MOD)

Part 10:2 Classification of areas

Explosive dust atmospheres